Welcome to Get Star Weld!

Welcome to Get Star Weld!

02 Aug, 2021

welding is a process and technique for joining metals or other thermoplastics by heat or pressure. There are several welding methods in Industrial application including Arc welding, stud welding, gas welding, thermite welding, electron beam welding. Welding has played a very important role in the development and infrastructure construction of modern society with its cheap and reliable metal connection technology. Some of main welding methods will be introduce in this article and the relevant advantages and disadvantages will be listed in order to guide the selection of the suitable welding method.

There are five commend welding methods in modern application and its all belong to Arc welding:

Hand arc welding(MMA)

Argon arc welding(TIG)

Carbon dioxide gas shielded welding(MIG)

Argon shielded welding(MAG)

Submerged arc welding(SAW)

Hand arc welding(MMA): Also know as electrode arc welding. By using stable burning arc that established between welding rog and the workpiece, which let to melt the welding rod and workpiece, therefore obtaining a firm welded joint. Welding material: iron, stainless steel, steel.

Why choose hand arc welding(MMA)? there are four reasons why chose Hand arc welding. The first point is that the equipment is simple, inexpensive, and easy to maintain. No complicated auxiliary equipment is needed during welding operation, only simple auxiliary tools are needed, which is convenient to carry. The second point is does not require auxiliary gas protection, and

out wherever the electrode can reach. Electrode arc welding is suitable for welding single or small batches of workpieces and welding seams which are irregular or not easy to achieve mechanized welding. The last point is a wide range of applications, which can weld most metals and alloys in industrial applications, such as carbon steel, low-alloy structural steel, stainless steel, heat-resistant steel, low-temperature steel, cast iron, copper alloy, nickel alloy, etc. In addition, electrode arc welding can also be used for welding of dissimilar metals, repair welding of cast iron and surfacing welding of various metal materials.

However, even though hand arc welding has so many advantages, it still has its limitations. Firstly, welders have high labor intensity and poor working conditions. When welding, the welder always performs manual operation and eye observation in a high-temperature and toxic smoke environment. Furthermore, hand arc welding has low production efficiency. Compared with automated welding methods, electrode arc welding uses a smaller welding current and requires frequent replacement of the electrode. Finally, very high requirements for welders, and the welder's operating skills and experience directly affect the welding result.

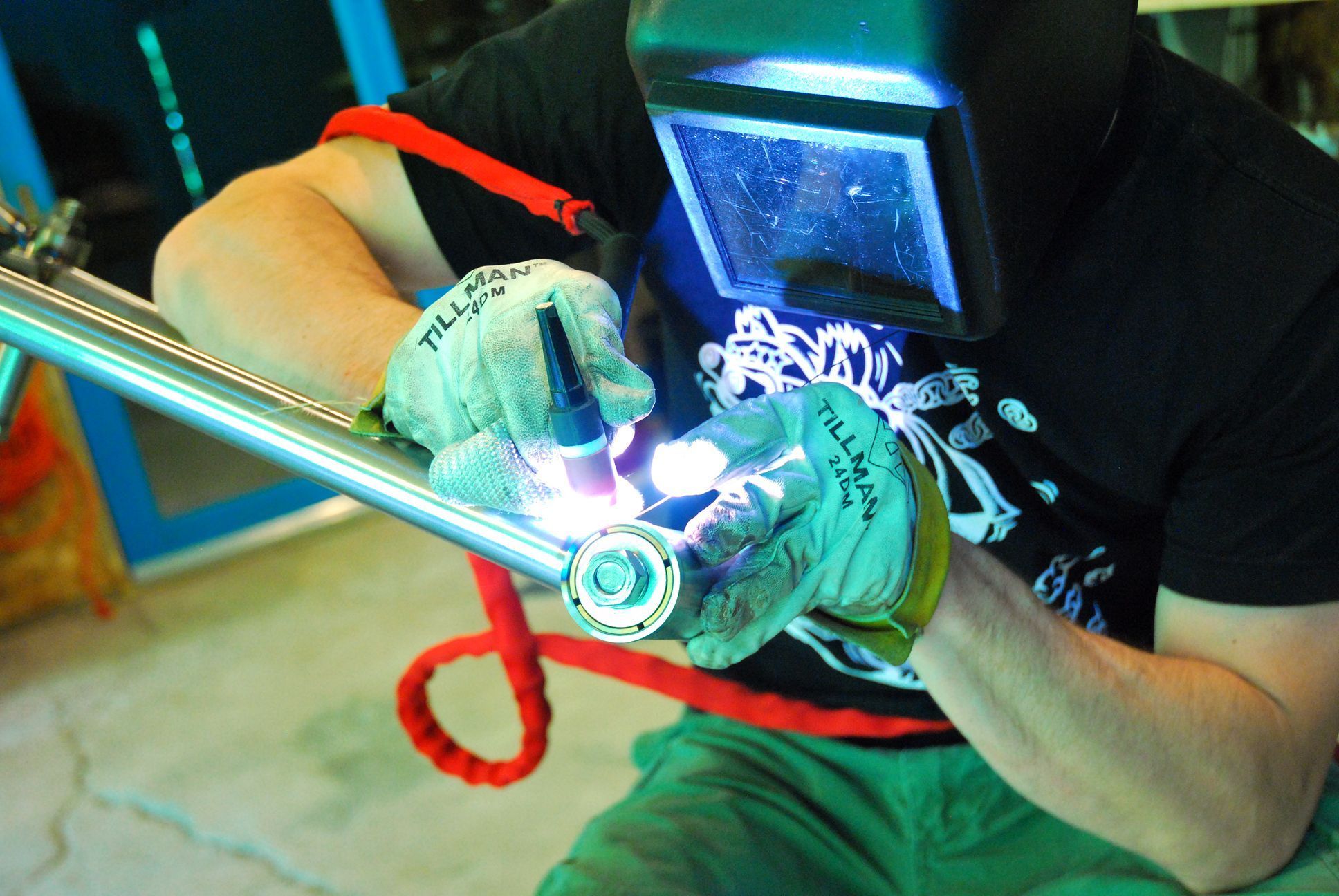

Argon arc welding also called Tungsten argon arc welding, it is a method in which argon is used as a shielding gas, and a tungsten electrode is used as a non-melting electrode. With the help of the arc generated between the tungsten electrode and the weldment, the base material is heated and melted to achieve welding. Argon gas is used to protect the weld metal and tungsten electrode molten pool, and will not be oxidized by air in the arc heating area.

Advantages of Argon arc welding:

1.good sealing performance, no air holes

2. AC argon arc welding can weld aluminum and aluminum-magnesium alloys which have active chemical properties and easy to form oxide films.

3. There is no slag or spatter during welding, the welding is concentrated, and the strong penetration.

4. Pulse argon arc welding can welds thin plates without penetrating, the machine forms fish scales naturally.

5.High-frequency no contact arc starting.

6.Suitable for carbon steel, alloy steel, stainless steel, refractory metal aluminum and aluminum-magnesium alloys, copper and copper alloys, titanium and titanium alloys, and ultra-thin plates 0.1mm, and can be welded in all directions, especially for complex workpieces

Disadvantages of Argon arc welding:

1. Due to the large heat-affected area of argon arc welding, the workpiece will often cause deformation, high hardness, blisters, local annealing, cracking, pinholes, abrasion, scratches, undercuts, or insufficient bonding force and internal stress damage after repair. Especially in repair process of precision castings and small defects are prominent particularly. In the field of repairing defects in precision castings, cold welding machines can be used to replace argon arc welding. Because the cold welding machine emits less heat, it can better overcome the limitations of argon arc welding and make up for the repair problems of precision castings.

2. Compared with electrode arc welding, argon arc welding is more harmful to the human body. The current density of argon arc welding is large and the light emitted is relatively strong. The ultraviolet radiation generated by its arc is about 5 to 30 times of ordinary electrode arc welding, infrared is about 1~1.5 times of electrode arc welding. The ozone content produced during welding is relatively high. Therefore, try to choose a place with better air circulation for construction, otherwise it will cause great harm to the body.

3. Difficult to weld the metals which have low melting point and easy to evaporation.

CO2 gas shielded welding(MIG) and Argon shielded welding(MAG) are high-efficiency welding method that relies on the arc between the welding wire and the workpieces to melt the metal. Carbon dioxide gas shielded welding is an arc welding method that uses metal welding wire as a melting electrode and inert gas (CO2) as protection. Referred to as MIG. Commonly used for soldering iron. Argon gas shielded welding is an arc welding method that uses metal welding wire as a melting electrode and inert gas (Ar) as protection. Abbreviated as MAG, it is often used for welding aluminum and stainless steel; but it has high cost and large radiation.

The characteristics of gas shielded welding:

1. High production efficiency

2. Low welding cost

3. Low energy consumption

4. Wide scope of application

5. Strong rust resistance: low hydrogen content in the weld

6. There is no need to clean the slag after welding, and the arc ignition operation is easy to monitor and control, which is beneficial to realize the mechanization and automation of the welding process.

Through the above introduction, you should have a certain understanding of how to choose welding products. If you are looking for a stable supplier, please click on the website: www.getstarweld.com. We are originate from 1987, Get Star Weld is the Global One-Stop Welding and Cutting Service Provider . Experienced in develop, produce and sale welding/cutting machines and accessories (ARC, TIG , MIG and Plasma ). Supply completed range of welding/cutting accessories including torches and consumables, gas regulator , helmet and glove ,cable coupling device, welding wire ,tungsten electrode , more than 5000 choices.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse viverra mauris eget tortor.